Transformer manufacture in India should reflect quality, efficiency, and longevity — qualities that distinguish premium products from lower-grade options.

The manufacturing process of a transformer begins with detailed design and engineering. Our team of engineers collaborates with clients to understand their specific requirements, including voltage, current, and environmental conditions. Based on these parameters, we design the transformer to meet optimal operational efficiency.

During the design phase, various factors such as the material used for the core and windings, insulation, and cooling systems are considered. We use advanced design software to create blueprints and simulations, ensuring the transformer’s performance is optimized for its intended application.

The core of a transformer is made from high-quality silicon steel sheets that are cut into precise laminations. These laminations are stacked together to form the transformer’s magnetic core, which plays a vital role in energy transfer. The quality of the core material directly impacts the efficiency of the transformer.

At Anand Steemet, we use high-grade, low-loss silicon steel to ensure minimal energy loss and improved efficiency. The core is then assembled using advanced techniques to ensure it is compact and well-structured. Precision in the fabrication process is essential to ensure that the transformer operates without energy loss or overheating.

The winding process involves wrapping copper or aluminium wire around the core to create the primary and secondary windings. These windings are crucial in determining the transformer’s voltage rating and efficiency. We use high-quality copper or aluminium wire, known for its excellent conductivity, to ensure optimal energy transfer.

The windings are carefully wound around the core with precision to avoid any shorts or overlaps. Automatic winding machines are used to maintain uniformity and consistency, ensuring that the number of turns on each coil matches the specifications for the required voltage ratio.

Insulation is a critical aspect of transformer construction, as it ensures the safety and reliability of the device. Each winding is insulated with high-quality material to prevent electrical short circuits. We use insulating paper, oil-impregnated paper, and other insulating materials to ensure that the transformer can handle high voltages without failure.

After the windings are insulated, the transformer is carefully assembled by connecting the primary and secondary windings. The insulated windings are positioned within the transformer tank, and the core is installed to complete the assembly. The tank is sealed to prevent the ingress of moisture, which could impair the performance of the transformer.

Once the transformer is assembled, it is filled with transformer oil, which serves two primary functions: insulation and cooling. Transformer oil is a high-quality insulating fluid that helps dissipate the heat generated during operation. The oil is carefully filtered to ensure no impurities are present.

In some cases, forced cooling systems are incorporated into the transformer design to enhanc

At ASIPL, our transformer manufacture in India process ensures top-tier quality. The process includes:

We work closely with clients to develop custom transformers based on voltage, current, and environmental factors.

We use premium silicon steel laminations to fabricate transformer cores that minimize energy loss.

Copper or aluminium wires are wound carefully using precision machinery, creating the required voltage ratio for the transformer.

We apply high-grade insulation to ensure the safety and longevity of the transformer, followed by precise assembly.

Our transformers are filled with high-quality transformer oil, which acts as both an insulator and a cooling agent.

We perform comprehensive testing, including high-voltage and load tests, to ensure every transformer is safe, reliable, and efficient.

Transformers are fully assembled, cleaned, and then securely packaged to prevent any damage during shipping.

ASIPL guarantees timely and safe delivery of every transformer, ensuring it reaches clients in perfect condition for installation.

e cooling efficiency. The oil is circulated through the transformer, providing a steady and reliable cooling process. Once the oil is filled, the transformer tank is sealed, and the oil level is checked to ensure it meets the required standards.

Quality control is an essential part of the manufacturing process at Anand Steemet. Each transformer undergoes a series of rigorous tests to ensure it meets performance, safety, and regulatory standards. Some of the key tests include:

Any transformer that does not pass these tests is rejected, and the necessary adjustments are made before further testing.

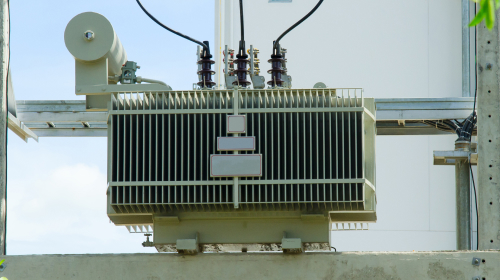

Once all tests are completed and the transformer passes quality control checks, the final assembly takes place. This includes attaching the transformer’s bushings, tap changer, and any other external components like cooling fans or radiators. The transformer is thoroughly cleaned and inspected to ensure that it is free from any defects.

After assembly, the transformer is carefully packed to protect it from any damage during transportation. We use robust packaging materials and cushioning to ensure the safe delivery of transformers, whether locally or internationally.

After packaging, the transformer is ready for delivery to the client. At Anand Steemet, we prioritize timely delivery and efficient shipping. Our logistics team works closely with trusted transport providers to ensure safe and on-time delivery of the transformers to various locations. We ensure that the transformer reaches the destination in perfect condition and ready for installation.

You will find yourself working in a true partnership that results in an incredible experience, and an end product that is the best.