Common Transformer Failures and How to Prevent Them?

Date: May 12th, 2025

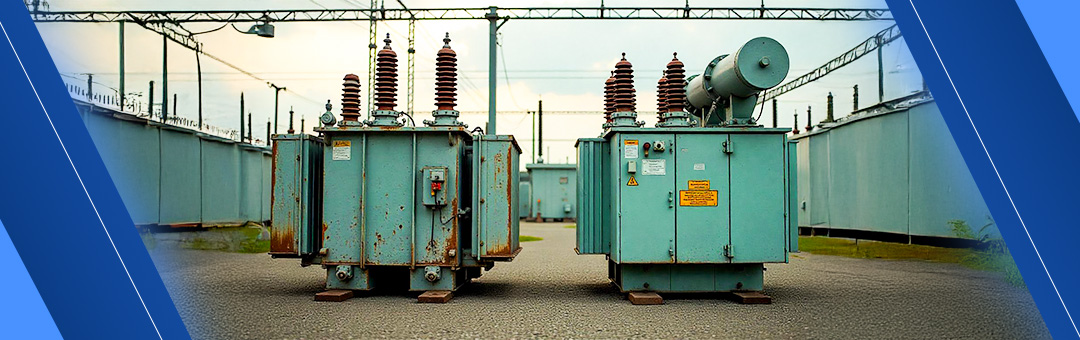

Transformers are inherently crucial to the electrical network in any power distribution system. From industrial plants to substations, the transformers guarantee effective voltage regulation and energy transfer. As with all electrical equipment, though, transformers can fail, causing expensive downtime, safety risks and plant disruptions.

Familiarising oneself with the most prevalent transformer failure modes and their prevention methods can assist organisations and transformer manufacturers in India in safeguarding their assets as well as enhance reliability.

Transformer Issues and Step to Troubleshoot them

Below is listed some of the common issues that mostly arise with transformers along with the methods that helps us troubleshoot them.

1. Insulation Breakdown

Breakdown of insulation is one of the most listed reasons for transformer failure. Insulation materials, by design, hold immense capability of withstanding high electrical stress levels, yet exposure to heat, humidity and contaminants over time might open up the chances to compromised integrity. Once the insulation is compromised, it can cause short circuits or arcing within the transformer, leading to severe damage to the transformer.

Preventive maintenance is key to preventing insulation failure. Testing, including dielectric strength testing and measurement of insulation resistance, should be regularly performed to check the condition of the insulation system. Controlling water entry is also important by making sure the seals and gaskets of the transformer are intact. Keeping good quality oil in the oil-filled transformers will minimise the chance of insulation deterioration caused by contamination or oxidation.

2. Overheating and Cooling System Malfunctions

Overheating is also a frequent cause that impacts transformer life. It may be due to overloading, inadequate ventilation, faulty cooling systems or ambient temperatures higher than design limits. Sustained overheating hastens insulation ageing and raises the risk of total failure.

For controlling overheating possibilities, transformers are to be driven within rated capacities.

Temperature sensors and thermal relays can be fitted to continuously monitor operating parameters. Defects in fans, radiators or oil pumps are to be replaced at once. Most organisations advise a reputed transformer manufacturer in India to choose models that have the latest cooling technologies and are best fitted for the ambient conditions prevalent at the location.

3. Electrical Surges and Lightning Strikes

Transformers are also susceptible to external electrical disturbances like lightning and switching surges. These voltage transients can enter transformer windings, which ends up causing insulation deterioration or coil distortion. In areas prone to frequent thunderstorms or rundown grids, the risk is considerably magnified.

Surge protection equipment also plays an undeniable role in protecting transformers against electrical surges. The installation of lightning arresters, surge suppressors, ground systems, etc., will redirect excess voltage from delicate transformer elements. A well-established transformer manufacturer in India often designs customised transformers with built-in surge protection systems according to regional requirements. Periodic checking of these devices ensures they function effectively in the long term.

Choosing the Right Manufacturer Makes a Difference

As maintenance practices are unavoidable, the choice of the transformer in the first instance is also crucial. Most failures fall under the proximity of improper design, low-quality materials or incompatibility with the intended application. A top transformer manufacturer in India provides strict quality control, extensive testing procedures and compliance with international standards that greatly lowers the likelihood of premature failure.

In addition, collaboration with a seasoned transformer manufacturer in India provides access to technical assistance and performance information years after the initial investment. Their knowledge of local power issues enables them to provide solutions tailored for efficiency, durability and safety.

Transformers are the backbone of every electrical network, and knowledge of their failure modes is critical for the maintenance of uninterrupted and safe operations. Overheating and electrical surges, along with insulation breakdown, are some of the most frequent causes of transformer failure, yet each can be eliminated with good planning and maintenance.

No less significant is the function of a sound transformer manufacturer in India, whose skill and quality control offer the basis for long-term performance. Investing in preventive measures and teaming up with reliable manufacturers can help companies and utilities guarantee that their transformers run safely and efficiently for years to come.

Additional Reading: