How Transformer Design Has Evolved Over the Last 50 Years?

Date: November 25th, 2025

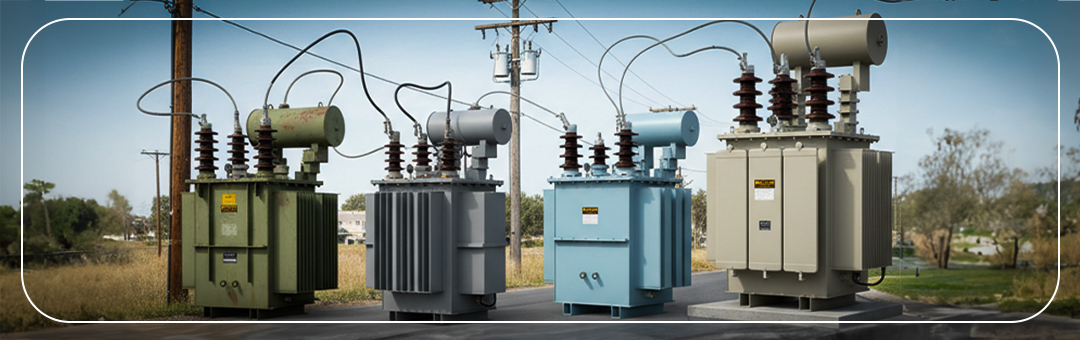

Power management and electrical infrastructure have advanced quite a lot over the past 50 years. The modest transformer, a tool that rarely draws public notice but is extremely important to the transmission of energy, is the central figure of this advancement. Today’s transformer manufacturer in India operate in a world where materials are changing, and monitoring systems are becoming more intelligent.

Gaining knowledge about how transformer design has evolved over time can help us better understand how our power networks have become more reliable and prepared for the future.

Materials and Engineering Innovations

Transformers were constructed with heavier core structures and bulkier materials fifty years ago. Although the early designs worked well, they needed more frequent maintenance and had higher energy losses. The application of core laminations has been improved by engineers over time, especially with the advent of cold rolled grain-oriented steel. As a result, transformer performance in both urban and rural networks was enhanced and core losses were decreased.

Amorphous metal cores and resin-impregnated cores have improved energy efficiency and further decreased losses. Enhancements in winding methods have also been crucial. Transformer lifespan used to be shortened by the windings, which increased the susceptibility to heat fluctuations.

Greater thermal endurance is made possible by modern winding designs, which prolong operational life and lessen insulation degradation. The increasing need for dependable electricity to support growing data centres and industries is reflected in each of these developments. Global technical standards that prioritise durability and reduced environmental impact must now be followed by a transformer manufacturer in India.

Shift from Manual Oversight to Smart Monitoring

Transformer maintenance used to be mostly reactive in previous decades. When scheduled cycles or failures occurred, technicians would check the equipment. Unexpected errors could result in expensive recovery and extended outages. Predictive reliability became critical as the commercial and industrial sectors expanded.

This landscape was changed by digital monitoring. Transformers with sensors and data analytics built in have made it possible for networks to monitor temperature changes, moisture levels, and load trends in real time. Operators now understand the health of their equipment without waiting for a breakdown. Rather, they are able to precisely plan maintenance tasks and foresee possible problems. In important industries, this change has very much increased uptime and decreased operational risks.

For a transformer manufacturer in India, offering intelligent monitoring capabilities is now a competitive necessity. Adding up to supporting automatic fault isolation, smart transformers can interface with grid management systems to facilitate seamless integration. This feature is particularly important in areas with high population densities where hospitals, schools, and commercial buildings depend on a consistent power supply.

Growing Focus on Sustainability and Future Readiness

Transformer design is increasingly influenced by environmental responsibility. Mineral oil has historically been used in transformers for cooling and insulation. Although mineral oil works well, it is not safe for the environment and can be dangerous if it leaks. Biodegradable oils derived from ester have become a more environmentally friendly option in recent years. These oils are especially helpful in residential or environmentally sensitive areas because of their higher fire safety ratings and lower environmental impact.

In the meantime, energy efficiency requirements keep rising. Reducing energy waste across power grids is both a climate responsibility and an economic priority. Modern transformers are therefore made to function as efficiently as possible even when the load is variable. Another force behind change is the incorporation of renewable energy.

Transformers used in wind and solar power must be able to manage varying input levels while preserving grid stability. It is now necessary for a transformer manufacturer in India to create goods that support both traditional and renewable power systems at the same time.

With the continued integration of digital automation and materials that provide even higher efficiency, the evolution is expected to continue in the future. Modern transformers will play a more important role than ever as the world shifts to cleaner energy use and increases demand for electricity. The current focus for any transformer manufacturer in India is on fusing innovation and dependability to make sure that future power networks continue to be flexible and sustainable.

To continue learning about Transformer Oil Testing & Lifecycle Management, we recommend exploring our blog